How to establish your health control plan? What is this ? What are the obligations for the restaurant? This is what we will see in this part entirely dedicated to hygiene, taken from the overall training for catering entrepreneurs that you will find by following this link!

Definition of the Health Control Plan

THE Health Control Plan (PMS) is a set of documents describing the means implemented by an establishment to ensure hygiene and food safety of its production in relation to microbiological, physical, chemical and allergenic dangers.

It ensures that the means necessary to ensure the objective of protecting consumer health are implemented.

Each operator must establish its own PMS adapted to the establishment and update it regularly.

In other words, it is a document that you will formalize, and who will reference all good practices related to hygiene, what you are going to do apply, and of which you are going control the right application.

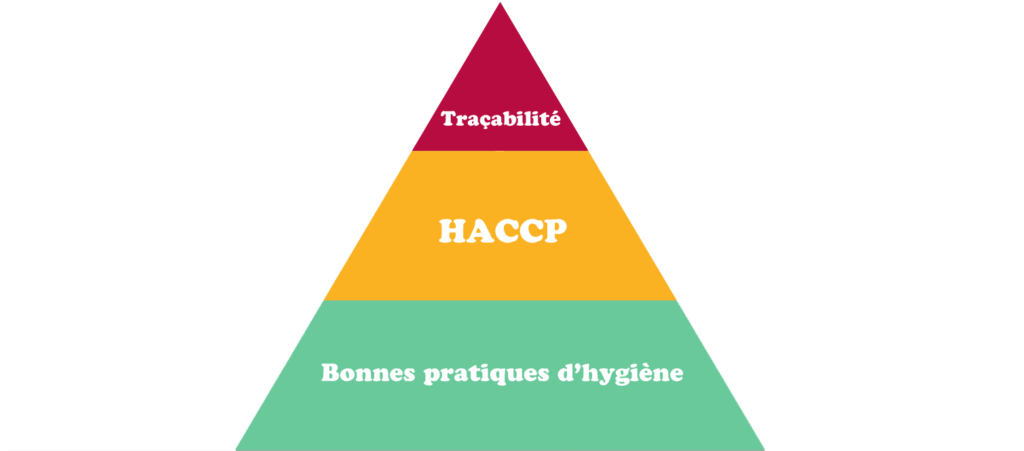

Now that we have defined the theoretical part, here is what the PMS contains in practice:

- Good hygiene practices.

- The HACCP plan (Hazard Analysis and Critical Control Points, i.e. the analysis of hazards and critical points for their control).

- Traceability upstream (from the supplier) and downstream (to the customer).

Don't panic, I will try to explain things to you simply and guide you step by step so that you can build this famous document.

We will therefore break down the three main parts above into different sub-parts, in the exact order in which they should appear in your Health Control Plan.

In other words, I invite you to read each chapter below, then to build your plan by taking and adapting what I summarize for you here, part by part, in addition to your personal research!

Good Hygiene Practices (GHP)

Good Hygiene Practices (GHP) constitute one of the three parts of the Health Control Plan (PMS).

THE BPH are a set of rules that you will have to formalize, communicate and whose execution you will have to control.

They are made up of the following eight parts. For each part, you can follow the link to consult the content.

- The pest control plan

- The water supply

- Temperature control

- Checks upon receipt of goods

Read the sub-parts one by one, quietly, and once you are familiar with the GHP part, you can move on to the next step, namely the HACCP method.

All these sub-sections are not yet developed, they will be developed over time, stay tuned…

The HACCP method

HACCP means Hazard Analysis and Critical Control Points or the analysis of risks and critical points for their control.

In other words, HACCP is a working method that you will have to follow in order to identify, evaluate and control significant dangers with regard to the food safety of your establishment or your food laboratory. Its objective is to minimize the risk of foodborne illnesses. Food must be safer for consumers.

HACCP is based on 7 principles:

- Hazard analysis.

- Setting critical control points

- Setting critical thresholds.

- Setting up a monitoring system.

- Corrective actions in the event of failure to control a critical point.

- Application of verification procedures to confirm that the HACCP system is operating effectively.

- Creation of a file in which all the procedures and all the statements concerning these principles and their application will appear.

This whole part will be developed soon… stay tuned!

Traceability

Traceability requires the operator to take responsibility for the choice of the traceability system implemented in his establishment. The latter has an obligation of result, but no obligation of means.

Traceability must therefore retrace the path taken by a product from its production (and therefore from the delivery of the products which constitute it) to its distribution.

Two types of traceability must be put in place by the establishment:

- Upstream traceability, the supplier-product link

- Downstream traceability, the customer-product link

Traceability thus makes it possible to withdraw or recall a product likely to present a risk to public health and to avoid TIAC (Collective Food Toxicity Infection).

This is the third part of your Health Control Plan.

It will also be developed soon…